Services

Hydraulic Completion Units

Our patented Hydraulic Completion Units (HCU) are developed with safety, efficiency, and a Data Acquisition System as the leading design concepts. Our disruptive HCUs specialize in the completion and intervention of record-breaking laterals, multi-well pads, high-pressure operations, and complex fishing jobs.

- Patriot Series

- Lonestar Series

Rental And

Specialized Services

We strive to provide a one call solution for all your completion and well servicing needs.

- 10K & 15K Blow out Preventers

- 5K Hot Tap Kit

- Torque and Test Services

- Data Analytics

- Well Control Training

ENGINEERING & ANALYTICS

Our DWS Engineering and Analytics department provide innovative solutions from pre-job planning and design, to wellsite data analytics that deliver immediate real-time operational improvements.

We are committed to leveraging technology & data to provide customers with end-to-end engineering support that creates true measurable cost savings and value.

MISSION STATEMENT

To serve our customers with quality analytics & reliable engineering solutions

BoreSite® is a patented data acquisition system (DAS) exclusively designed to capture and transform wellsite data into valuable insight for operators within the upstream oil & gas industry.

Key Features:

Our live feed data provides real-time visibility into operation(s) anywhere in the world, enabling anyone to understand on-site performance and make immediate corrections.

CUSTOMIZABLE ALARMS AND DASHBOARDS

From remote monitoring of pit levels to setting drill-out operational parameters & notifications, our fully customizable dashboard & user reports allow you to view the data that matters most – delivered the way you want it.

REAL-TIME AUTOMATED PLUG TRACKER

Our real-time automated plug tracker improves data accuracy, provides plug by plug KPIs, and eliminates pen to paper data collection during the frac plug drill-out operation.

BUILT-IN DATA ANALYTICS AND USER REPORTS

Built-in data analytics providing access to current & historical well KPIs, After-Action Reviews, NPT reports, Rig comparisons, and other key data sets to drive continuous improvement.

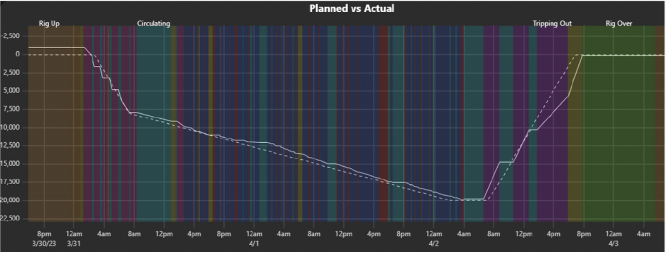

PLANNED VS ACTUAL (PVA)

Our BoreSite® Planned vs. Actual (PvA) KPI feature allows your team to make immediate onsite improvements by comparing historical data vs your current operations in real time.

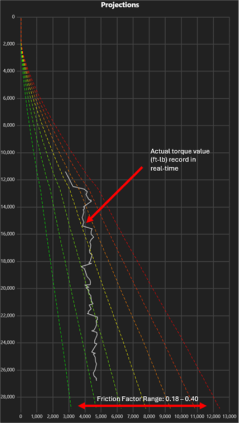

Modeled Torque vs. Actual

A patented process within BoreSite® allows modeled torque and drag simulations to overlap actual live drilling torque, resulting in substantial cost savings through chemical and fluid efficiencies.

BORESITE® DATA VAULT

Maintain full internal control of your data through our BoreSite Data Vault.

This cloud-based portal delivers infinite secure data retention and is supported by Microsoft authentication; allowing you to access your historical well data anytime, anywhere.

- Row-level security – only able to directly access your data.

- Instant download capabilities including raw CSV formats for internal analysis.

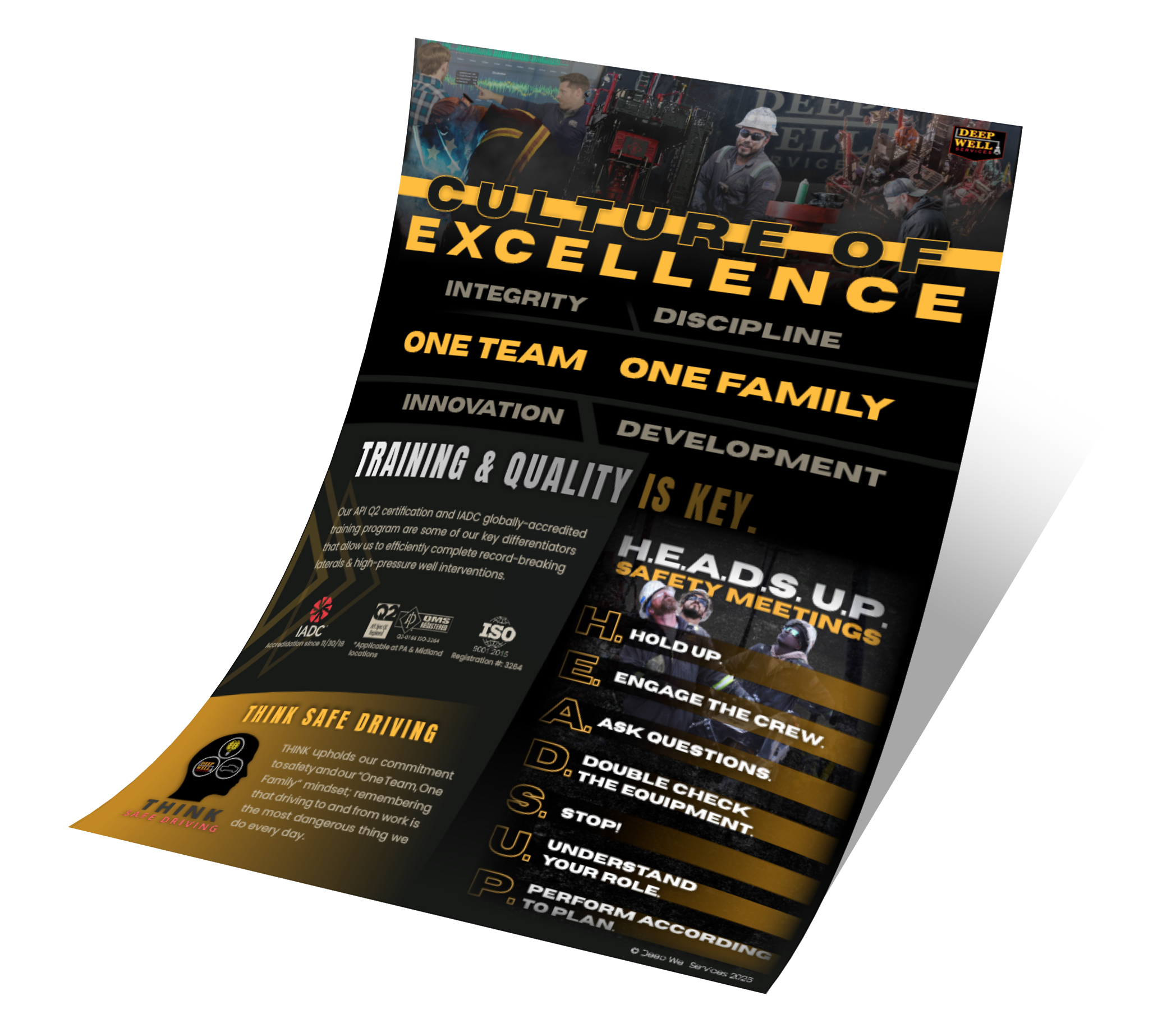

OUR CULTURE OF EXCELLENCE

ONE TEAM. ONE FAMILY.

We are an API/Q2 registered technology and training company focused on developing the most advanced Completion and Workover Packages on the market today, driven by patented data acquisition systems and IADC globally accredited trained crews.